Fiber laser welding machine

Fiber Laser welding machine is suitable for welding gold, silver, titanium, nickel, tin, copper, aluminum and other metals and their alloy materials. It can achieve the same precision welding between metals and dissimilar metals. It has been widely used in aerospace, shipbuilding, and instrumentation. , Mechanical and electrical products, automobiles and other industries.

|

| | |

| Machine model | CH-HW |

| Max laser power | 2000W |

| Cable Length | Standard 10m, the longest 15m |

| Welding Speed | 0-120mm/s |

| Welding Thickness | 0.5-4mm |

| Welding Gap | ≤0.5mm |

| Positioning Accuracy | ±0.03MM |

| Working Voltage | 220v |

| Dimensions | 1100x620x1200mm |

| Weight | 230kg |

1.Electro-optical conversion efficiency up to 30%. 2. They are excellent beam quality, high energy density, and reliability, a wide modulation frequency;

3. 100,000 hours of lifetime, free maintenance; Low energy consumption.

1. Automatically adjust the temperature according to different working environment, no need to change settings parameters. Reduce

the temperature of the laser source and the laser head through water circulation, thereby protecting these two main parts. 2. The chiller has functions such as water flow protection and water temperature protection. If the chiller is not opened or the water

flow is insufficient, the laser will not be generated when the water temperature is too high, so as to protect the laser.

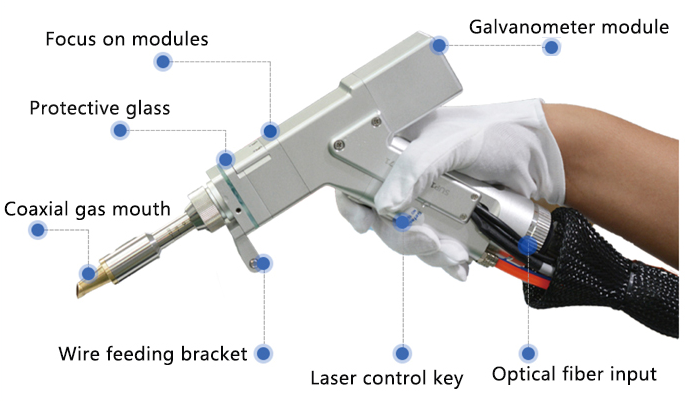

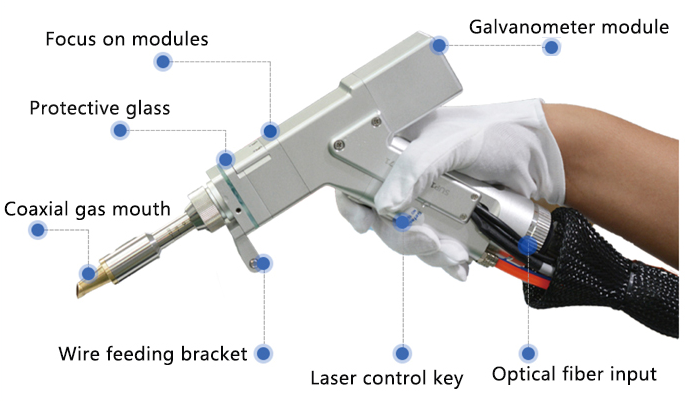

Portable Laser Welding Head

1. High precision professional laser welding head.2.Portable and flexable, intergrated gas protection system

What is the laser welder application?

Laser welding technology and laser welding machine are widely used in manufacturing, powder metallurgy, automotive industry, electronics industry, biomedicine.The laser beam is easy to focus, align and be guided by optical instruments. It can be placed at an appropriate distance from the workpiece, and can be guided between tools or obstacles around the workpiece. Other welding methods cannot be used due to the above-mentioned space limitations. Laser welding is one of the important aspects of the application of laser material processing technology.

Factory address:Room 102, Unit 2, Building 33, 16-1 Xiangtan Road, Chengyang District, Qingdao city, Shandong Province

Factory address:Room 102, Unit 2, Building 33, 16-1 Xiangtan Road, Chengyang District, Qingdao city, Shandong Province Mobile:+8613583297377

Mobile:+8613583297377 Zalo:+8613583297377

Zalo:+8613583297377 WhatsApp:

WhatsApp: Wechat:+8618561758788

Wechat:+8618561758788